Next generation materials, designed using AI

Empowering industries with advanced materials, tailored for specific applications and outcomes, designed using AI.

To meet a rapidly evolving industry, you need new materials.

Slow materials innovation is becoming a bottleneck across industries, hindering performance, driving up costs and delaying the adoption of new technologies at scale. This is mainly caused by the large number of lengthy and costly experimental trials required to understand and optimize the material properties. Therefore, new materials development has historically been a low Return-on-Investment (ROI) activity due to high initial costs and lengthy timelines.

from the lab to market

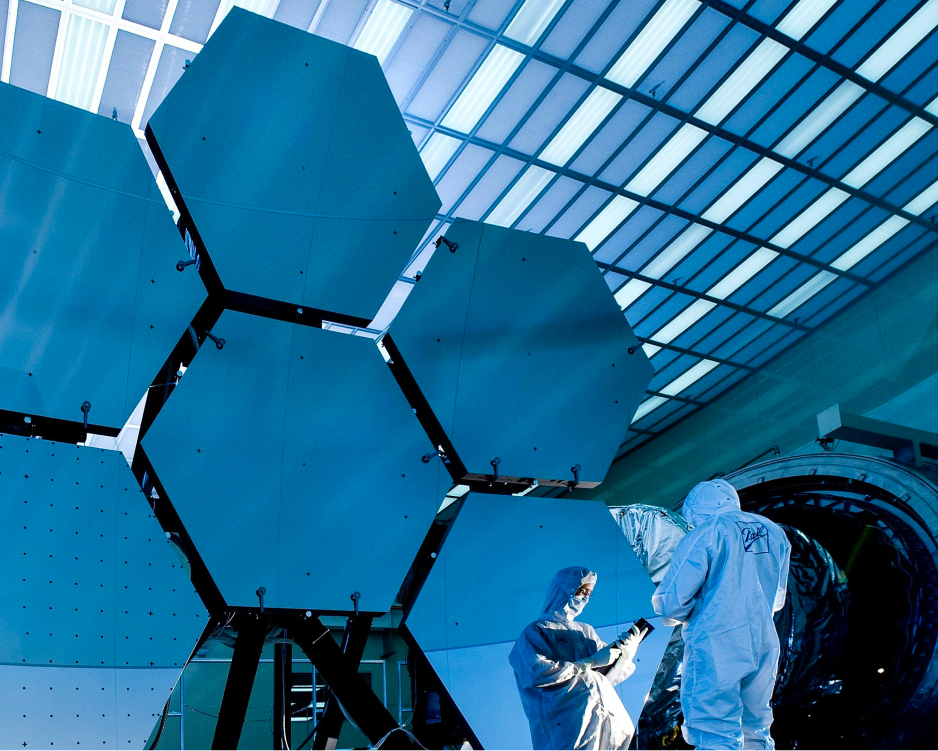

Designed with AI and Multi-scale Simulations

Our Rapid Alloy Design (RAD) platform overcomes the limitations of traditional alloy design. It leverages two advanced technologies: Artificial Intelligence and Multi-scale Simulations.

AI to optimize alloy compositions

We use purpose-built, physics-informed AI models to predict optimal alloy compositions and properties with high precision and speed. Our models are trained on extensive materials datasets, enabling them to identify and model complex relationships between materials, processes, structures, and properties. These AI models work in tandem with multi-objective optimizers, balancing conflicting design objectives to achieve the best possible outcomes. This approach drastically reduces development time and costs, enabling the rapid design and optimization of high-performing, reliable materials for industrial applications.

Integrating simulations at all size scales to model real-world performance

We use multi-scale simulations to evaluate new alloys comprehensively. By integrating simulations at varying size-scales, such as nano, micro, meso, and macro scales, we understand how interactions at the smallest scales drive real-world performance. This approach allows us to predict performance under various conditions, ensuring materials meet specific criteria and reducing the need for extensive experimental testing.

We utilize in-house generated datasets to train our models

In the materials science sector, data is often scarce. To address this, we generate our own hybrid datasets through a combination of experiments and simulations. This approach yields more consistent, higher-quality data across a diverse range of scenarios. As a result, our models, trained on this proprietary data, demonstrate superior performance and reliability.

Rapid Alloy Design vs Traditional Methods

We work across the Global Specialty and High-performance Alloy Market

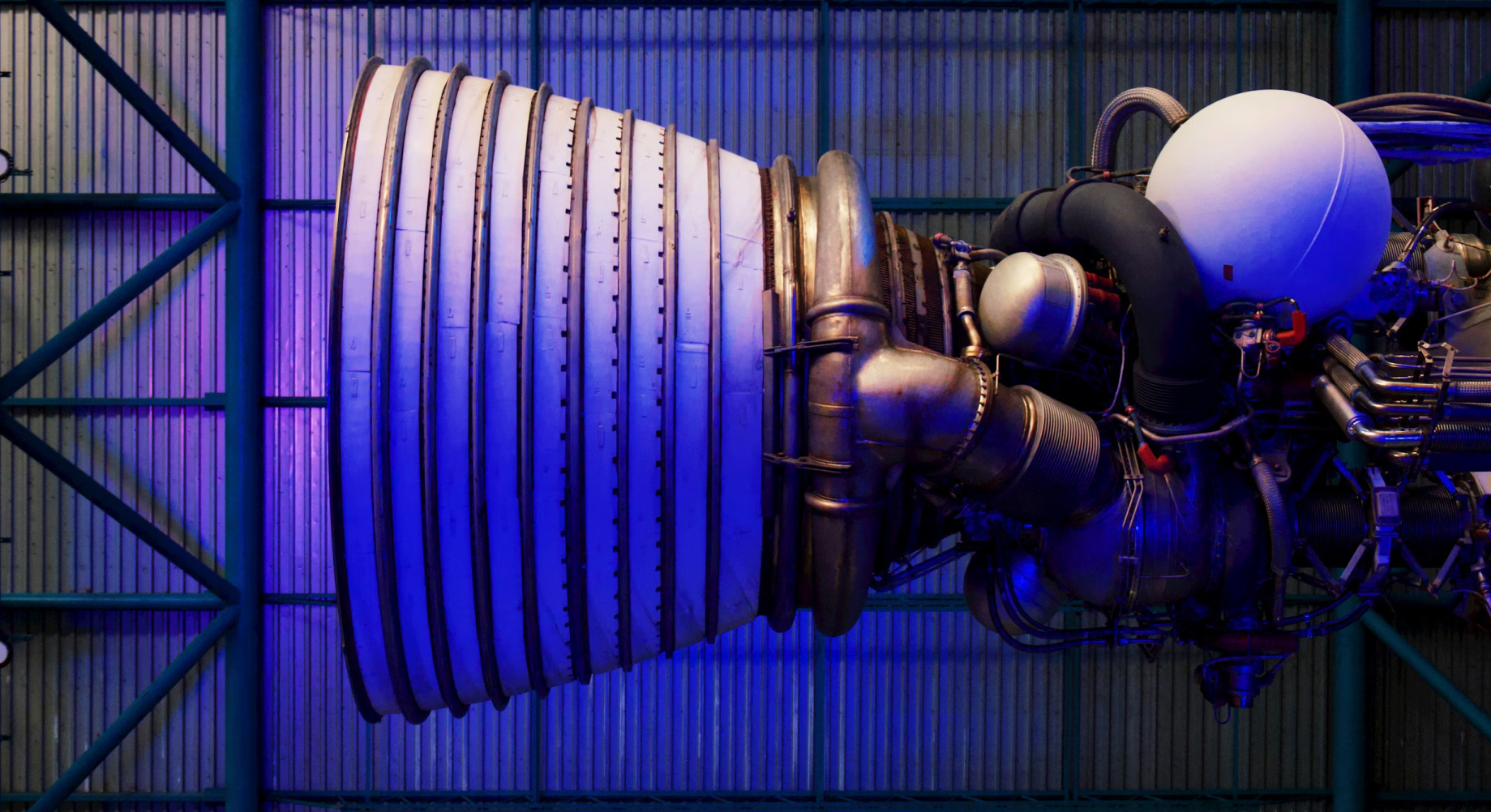

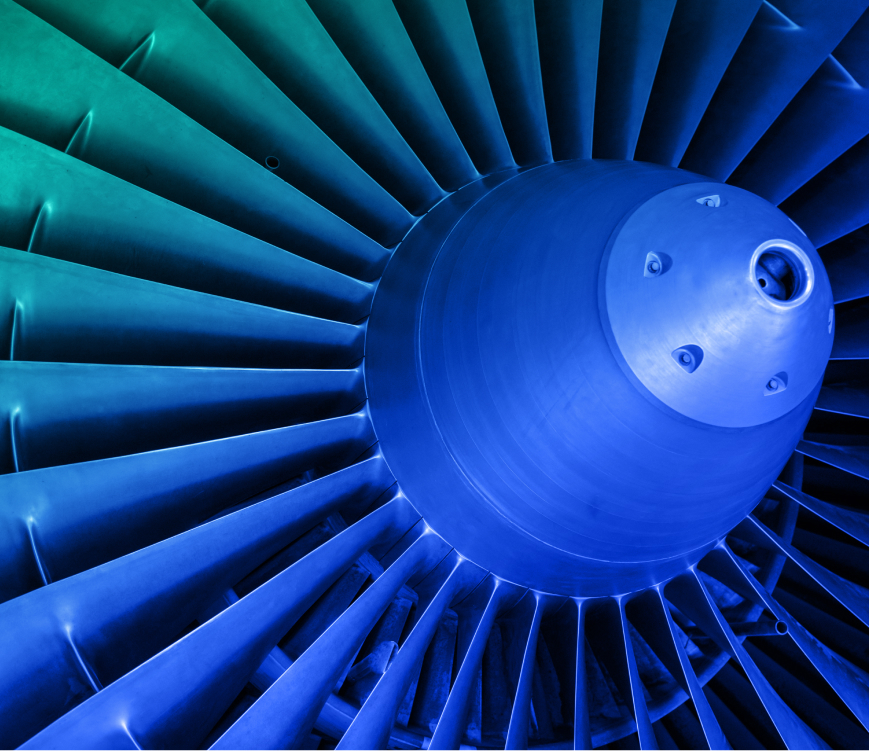

Aerospace

Custom alloys enhance durability, reduce weight, and improve fuel efficiency, driving innovation and ensuring compliance with safety standards.

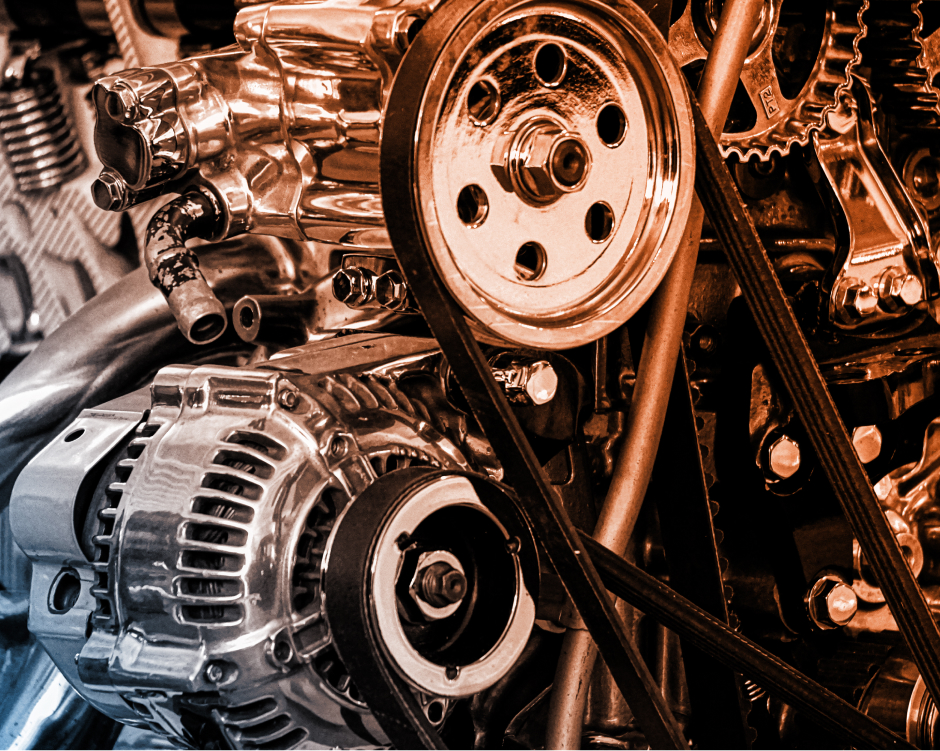

Automotive

Tailored alloys offer lighter, stronger materials that boost fuel efficiency, safety, and sustainability, enabling innovative vehicle designs.

Energy

Specialized alloys withstand extreme conditions, improving equipment durability and efficiency, reducing maintenance costs, and ensuring reliable energy production.

Defence

Advanced alloys provide superior strength, durability, and lightweight properties, enhancing military equipment performance and supporting cutting-edge technologies.

Mining

Durable alloys withstand harsh environments, enhancing equipment longevity, reducing maintenance, and improving mining productivity.

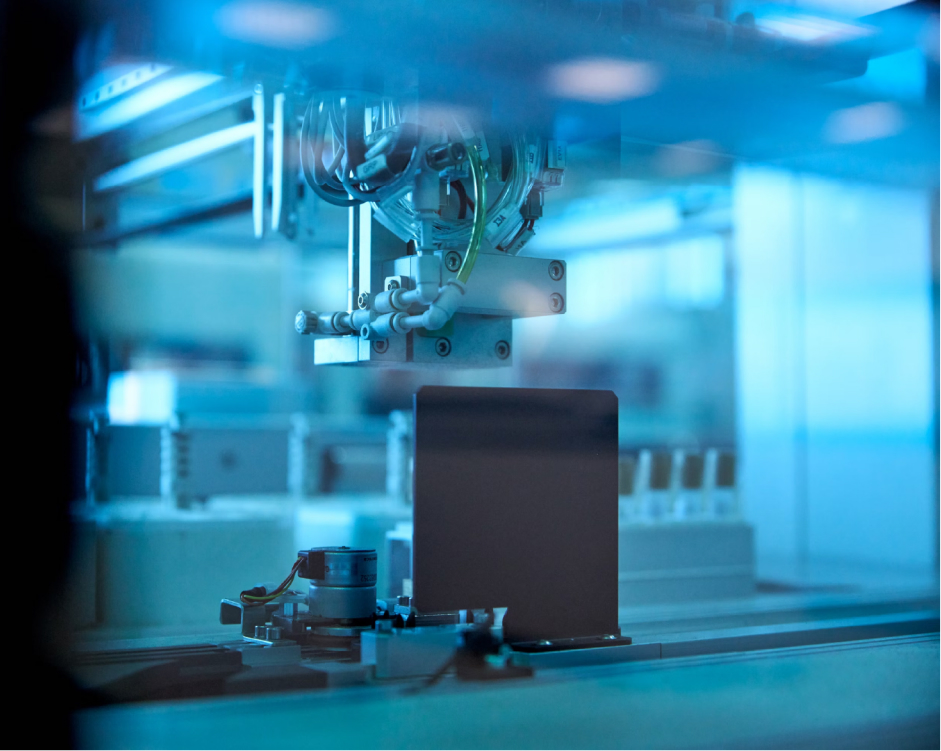

Advanced Manufacturing

Tailored alloys improve product performance, durability, and design flexibility, driving innovation and efficiency in manufacturing processes.

Develop better products faster while reducing your costs

Stay competitive in the ever-evolving engineering industry with custom-designed alloys